Successful Assembly of Fireclay Bottom Blocks for Egypt Project

Source:http://en.hnhenglinc.com/news/26.html Release time:2024-11-21 Click:354

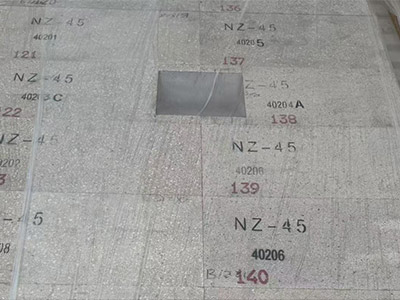

In the glass industry, the furnace bottom is one of the most critical core components. Recently, our company successfully completed the pre-assembly of large fireclay blocks for the furnace bottom, For exporting to Egypt glass bottle project. These fireclay blocks were made from high-quality refractory materials, subjected to rigorous manufacturing and processing to ensure that each block matches stringent quality standards.

The fireclay blocks produced by ‘HENGLI’ utilize an intelligent temperature control system during the firing process, ensuring uniform sintering throughout the material. During the processing stage, high-precision cutting and grinding equipment is employed, for achieving a tolerance of +0/-1mm.

Pre-assembly is also a crucial step in furnace construction. The pre-assembly of the furnace bottom blocks for this project was completed by an experienced professional team. They maintained strict requirements for the dimensions and shapes of the blocks, ensuring precise placement, gap size, and surface contact. Throughout the entire assembly process, the Hengli team maintained strict site control to ensure the furnace bottom achieved optimal flatness.

From the initial design communication to the final assembly, the Hengli team consistently adhered to the principle of "customer first," striving for excellence in every detail. This professionalism and commitment to customer needs highlight the reliability of the Hengli brand.

In recent years, our refractory materials have gained increasing attention and recognition in international markets. This project for Egypt not only demonstrates our technical expertise but also reaffirms our advancements in product quality, delivery timelines, and customer service.