Customer-Centric Approach: Ensuring Quality to Win the Market

Source:http://en.hnhenglinc.com/news/25.html Release time:2024-11-19 Click:379

In today’s highly competitive market, product quality is the cornerstone of enterprise growth and the key to earning customer trust. Recently, a key client visited our company for an inspection, taking a hands-on approach to quality control. This was not only a test of our production processes but also a thorough evaluation of our quality management system. The client’s high standards and strict requirements have reinforced our belief: quality is the foundation for securing a competitive edge in the market.

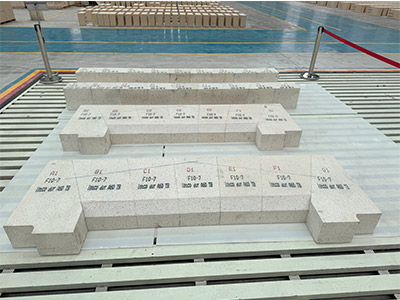

In the production of refractory materials, particularly large bricks for glass furnaces, our company implements stringent quality monitoring throughout all critical processes, including molding, firing,

and grinding. Each brick is meticulously checked to meet precise standards for dimensions, shape, and density. We utilize digital equipment to automate production, minimizing human error. During the inspection, the client carefully reviewed product appearance and performance while assessing the production line, equipment operations, and employee procedures. In response to the client’s feedback, we promptly addressed and improved any identified issues. This transparent communication and efficient execution not only earned the client’s trust

but also laid a solid foundation for long-term collaboration.

**Strict Quality Control: Building a Strong Reputation**

Ensuring quality is the cornerstone of sustainable development. To achieve the goal of delivering the best products, we focus on continuous improvement in the following areas:

1. Stringent Raw Material Selection

We ensure quality at the source by establishing a reliable supply chains and conducting rigorous testing on every batch of raw materials, eliminating substandard inputs from the

production process.

2. Optimized Production Management

Advanced equipment and automation technologies are employed to guarantee precision at every production stage. Real-time monitoring through digital management systems reduces errors and

enhances efficiency.

3. Comprehensive Quality Testing

We expand inspection protocols to cover all aspects, including appearance, performance, and dimensions. International-standard testing tools are used for random sampling to ensure consistency and reliability in every batch.

4. Employee Training on Quality Awareness

Regular training sessions instill the principle that “quality is life” into every team member. We empower frontline employees to identify and resolve issues, embedding quality consciousness into every process.

Winning the Market with best Quality

Strict quality control is not only a commitment to our clients but also the driving force behind our company’s long-term success. The recent client inspection was both a challenge and an opportunity

to enhance our quality management system. Moving forward, we will continue to refine internal processes, strengthen quality awareness across the organization, and implement rigorous standards at every production stage.

With quality as our guiding principle, we are committed to delivering the best products and services to secure our position in the market and earn lasting customer trust.