Description

► Description

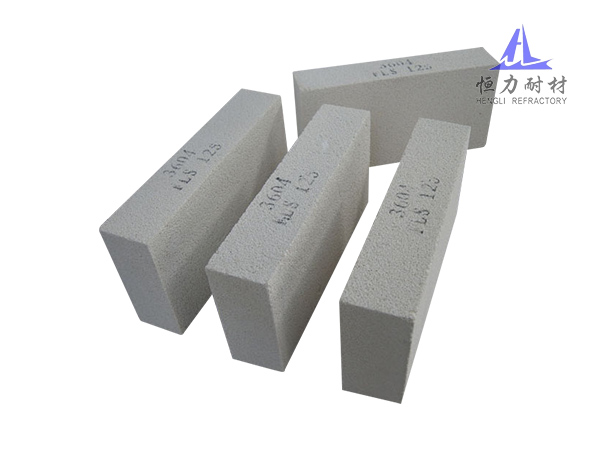

Mullite insulation bricks are high alumina refractories mainly made from good quality and pure raw materials. In generally, alumina accounts 40%-75%. Besides mullite, there are also glass phase as well as corundum which are good grade fillings. Mullite insulation bricks are widely used for lining in high temperature kilns such as shuttle kiln, roller kiln, glass furnace and petroleum kilns.

►Specifications

1.Low thermal conductivity, good heat insulation.

2.Low thermal melting point. Lightweight mullite insulating bricks save heat and energy.

3.Low impurity content, high temperature resistance; higher alumina content ensures good performance.

4.Customized shapes to reduce bricks quantity and cost.

5.Dense, compact and accurate structure, low porosity rate.

6.High loading temperature, corrosion resistance.

Typical Indexes

Brand | JM23 | JM26 | JM28 | JM30 |

| ASTM Brand | IFB2300 | IFB2600 | IFB2800 | IFB3000 |

| Classification Temperature (℃) | 1260 | 1450 | 1550 | 1600 |

| Bulk Density (g/cm3) | 0.55-0.6 | 0.78-0.8 | 0.88-1.0 | 1.0-1.1 |

| Cold Crushing Strength (Mpa) | 1.2 | 1.6 | 2.1 | 2.5 |

| Modulus of Rupture (Mpa) | 0.9 | 1.4 | 1.6 | 2.1 |

| Reheating Linear Change (%)CT-30℃X 8H | 1230℃ -0.5 | 1400℃ -0.5 | 1510℃ -0.5 | 1620℃ -0.9 |

| Thermal Expansion 1000℃(%) | 0.5 | 0.7 | 0.8 | 0.9 |

| Thermal conductivity(W/m.k) | 400℃ | 0.14 | 0.27 | 0.32 | 0.41 |

| 600℃ | 0.16 | 0.29 | 0.34 | 0.43 |

| 800℃ | 0.18 | 0.31 | 0.36 | 0.44 |

| 1000℃ | 0.20 | 0.33 | 0.38 | 0.45 |

| Al2O3 (%) | 37 | 54 | 64 | 72 |

| Fe2O3 (%) | 1.0 | 0.9 | 0.8 | 0.6 |