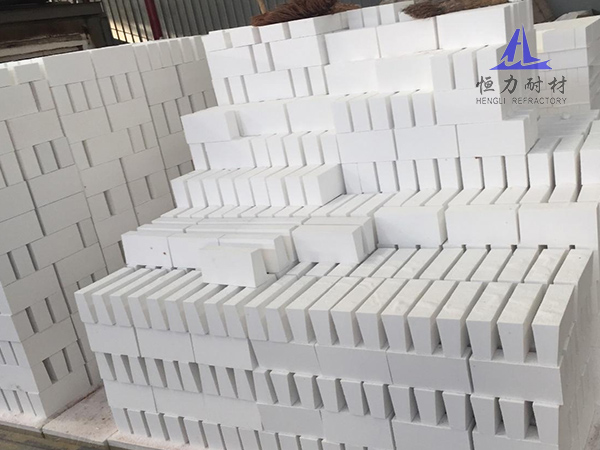

Zero-expansion silica bricks are also known as fused silica bricks or heat-shock resistant silica bricks. It has the characteristics of extremely low thermal expansion rate, excellent resistance to rapid cold and heat, good high temperature structural strength, and high SiO2 content. The product can be widely used in a variety of glass furnace, coke oven rapid hot-repair engineering, the product does not occur crack peeling phenomenon when used, close to zero low thermal expansion performance, so that the kiln after repair, long-term use of safe and reliable.

Main Usage:

In the chemical industry, it is mainly used as the top of glass melting-end and other parts. Because of its low expansion rate, high thermal stability and high compressive strength, zero-expansion silica bricks are easy to make large blocks, and the surface is smooth and free of carbon deposits.

Characteristics:

1. SiO2 content is more than 99%, excellent erosion resistance and acid resistance.

2. Low Fe2O3 content is less than 0.1%, no pollution to products (such as glass liquid, etc.).

3. The low flux index (Al2O3+2R2O) is less than 0.3%.

4. The thermal expansion rate is close to zero, and there is no need to reserve expansion joints when repairing, which increases the tightness of the masonry

5. Excellent thermal stability, the product will not preheating during hot repair, and the repair operation can be carried out directly under the high temperature of the furnace without stopping

6. After repair (hot repair), there will be no peeling and other phenomena, and it is safe and reliable for long-term use.

7. No need for long-term kiln baking after masonry; No preheating required.