High alumina brick is a kind of refractories, the main composition of this refractory brick is Al2O3.Aluminum trioxide (Al2O3) containing more than 48% aluminum silicate refractories.

►Details:

1.Made by bauxite clinker and binder through Crushing, Mixing, Shaping, Drying and high temperature Sintering.

2.Al2O3 content is 48%-80%, main mineral components are corundum and mullite phases.

3.Refractoriness is above 1770°C, refractoriness under load is 1420-1550°C.

4.Working temperature:1350°C -1650°C.

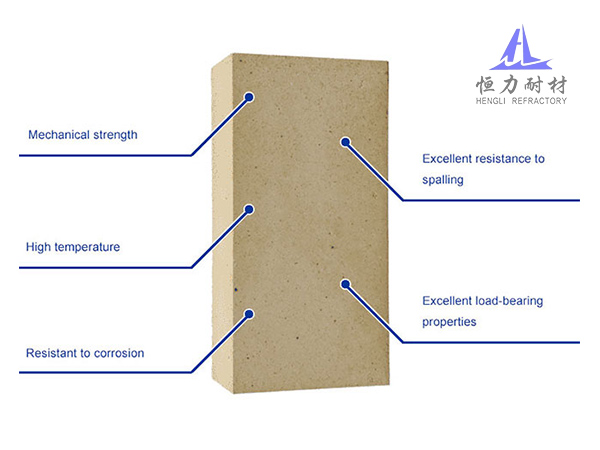

►Feature:

1.High mechanical strength;

2.Good thermal shock resistance;

3.Good resistance to abrasion and corrosion;

4.Good volume stability at high temperature;

►Application:

Iron & steel making industry

Blast furnace, hot-blast furnace(stove),pellet shaft furnace, hot metal ladle, steel ladle, tundish, soaking pit furnace, heat treatment furnace and etc.

Non-ferrous Metal industry

Smelting-furnace, refining-furnace, reverberatory furnace, converter furnace and etc.

Building materials industry

Such as cement kiln, glass kiln, ceramic kiln, lime kilns, kiln car, tunnel kiln and etc.

Energy& Incineration

Coke oven, general boiler, power generation boiler, circulating fluidized bed boiler, electric furnace, carbonroasting furnace, waste incinerators and etc.

Others

Petrochemical industry furnace

►Delivery

Package Information:

1. Packed in a 100cm*100cm fumigated wooden pallet with a waterproof plastic film cover, and tightened with plastic bandages.

2. We can also pack the goods according to your requirements.

Shipping:

1. FEDEX/DHL/UPS/TNT for samples.

2. By Sea for batch goods.

3. Customers specifying freight forwarders or negotiable shipping methods!

4. Delivery Time:3 days for common shape samples;15 days for special shape samples. Within 30 days for batch goods.